Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

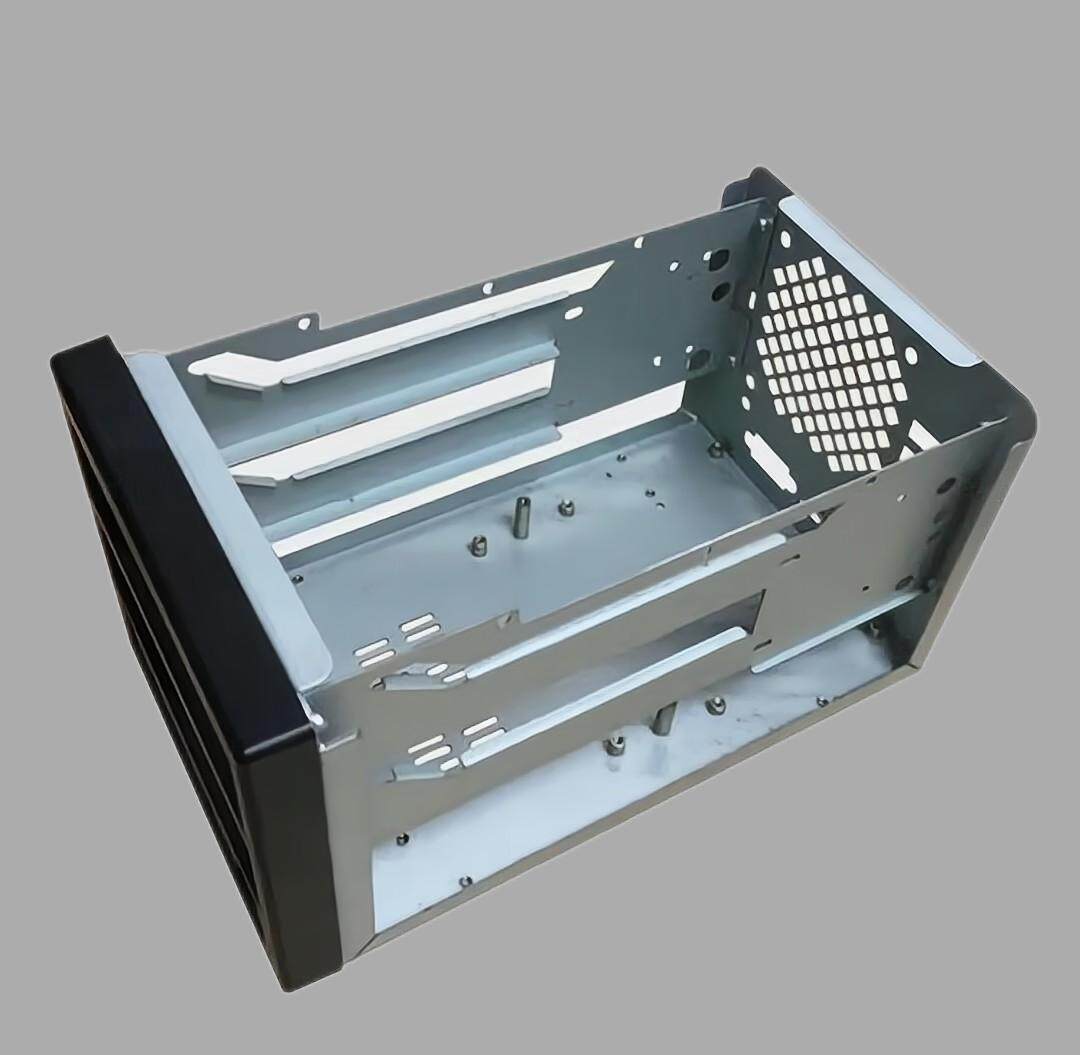

Power sheet metal sample

-

0.00 ~ 0.00/

10/ (Min. Order)

Our power sheet metal parts are meticulously designed to prevent rust and corrosion, with every detail crafted with exquisite precision. These parts are highly resistant to water and moisture, ensuring a dry and cool environment for your power equipment. Additionally, our sheet metal parts are incredibly durable and tough, providing a secure and protected environment for your power equipment.

Sheet metal processing is the key technology that sheet metal technical staff need to grasp, and also an important process of sheet metal products forming. Sheet metal processing is including the traditional cutting blanking, blanking processing, bending forming and other methods and process parameters, including a variety of cold stamping die structure and process parameters, a variety of equipment working principle and control methods, but also including new stamping technology and new process.

Power Sheet Metal Sample Feature

Aesthetically Pleasing Design: The power sheet metal parts boast an aesthetically pleasing design that adds a professional and polished look to your power equipment. These meticulously crafted parts are designed to prevent rust and corrosion, ensuring durability and longevity.

Water and Moisture Resistance: The sheet metal parts are meticulously designed to provide a high level of resistance against water and moisture, ensuring a dry and cool environment for your power equipment. With their meticulous design, these parts offer excellent protection against rust and corrosion, ensuring durability and longevity.

Rust and Corrosion Resistance: The power sheet metal parts are meticulously designed to prevent rust and corrosion, ensuring their longevity and optimal performance in various environments. These specially crafted parts are engineered to withstand the challenges of different conditions, providing reliable protection for your power equipment.

Power Sheet Metal Sample Advantages

Precision Engineering: The metal parts are meticulously designed and crafted with exquisite precision, ensuring a perfect fit and optimal functionality in power equipment applications. Every detail is carefully considered to guarantee the highest level of performance and reliability.

Customization Options: We understand that every power equipment is unique, which is why we offer customization services to meet your specific requirements. Our power sheet metal parts can be tailored to fit your equipment perfectly, ensuring optimal performance and functionality. Whether you need a specific size, shape, or design, our team of experts will work closely with you to create the perfect solution.

Application of Power Sheet Metal Sample

- Automotive Industry: For manufacturing car bodies, fenders, doors, hoods, and other structural components;

- Electronics Industry: Such as computers, laptops, smartphones, and tablets;

- Aerospace Industry: For producing aircraft structures, wings, fuselage, and engine components;

- Construction Industry: For producing various structural elements like beams, columns, pillars, and trusses;

- Industrial Equipment: Such as machinery, conveyors, storage systems, cabinets, and enclosures;

- Medical Industry: Including surgical instruments, hospital beds, diagnostic machines, and patient monitoring devices;

- Renewable Energy Sector: In the manufacturing of solar panels, wind turbine components, and electrical enclosures for renewable energy systems;

- Consumer Goods: Including household appliances, kitchen equipment, furniture, and exercise machines.