Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

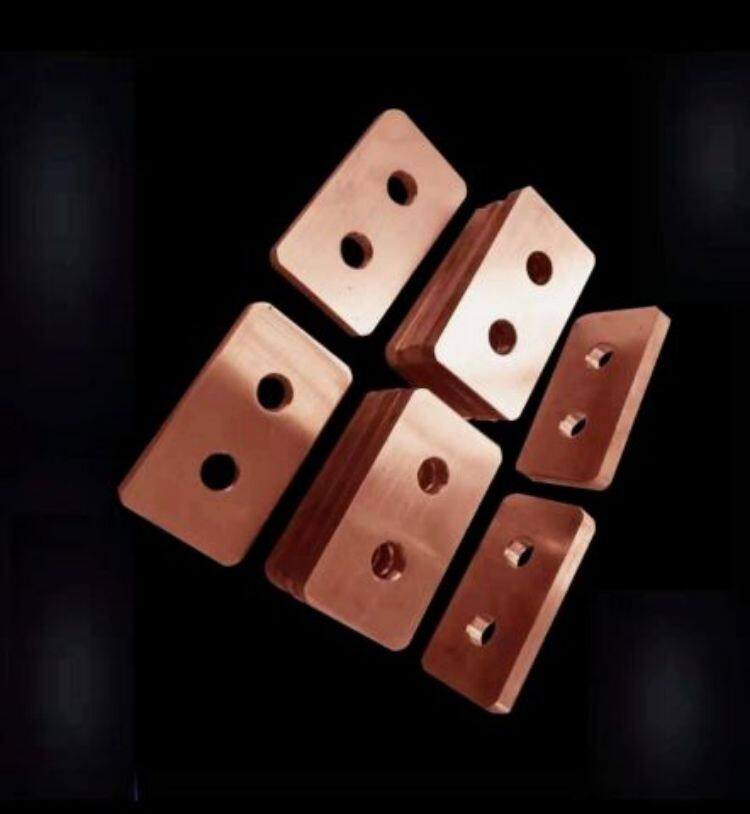

Copper Cutting - Custom Cnc Metal Cutting Service

-

0.00 ~ 0.00/

1/ (Min. Order)

The copper cutting parts are engineered to deliver exceptional process performance and unrivaled reliability, boasting excellent brazing stability. Utilizing cutting-edge cutting machines, these parts are meticulously crafted to ensure precise and flawless cutting edges, guaranteeing optimal functionality. Furthermore, they undergo meticulous oxidization treatment, offering superior protection against oxygen and enabling seamless conveyance.

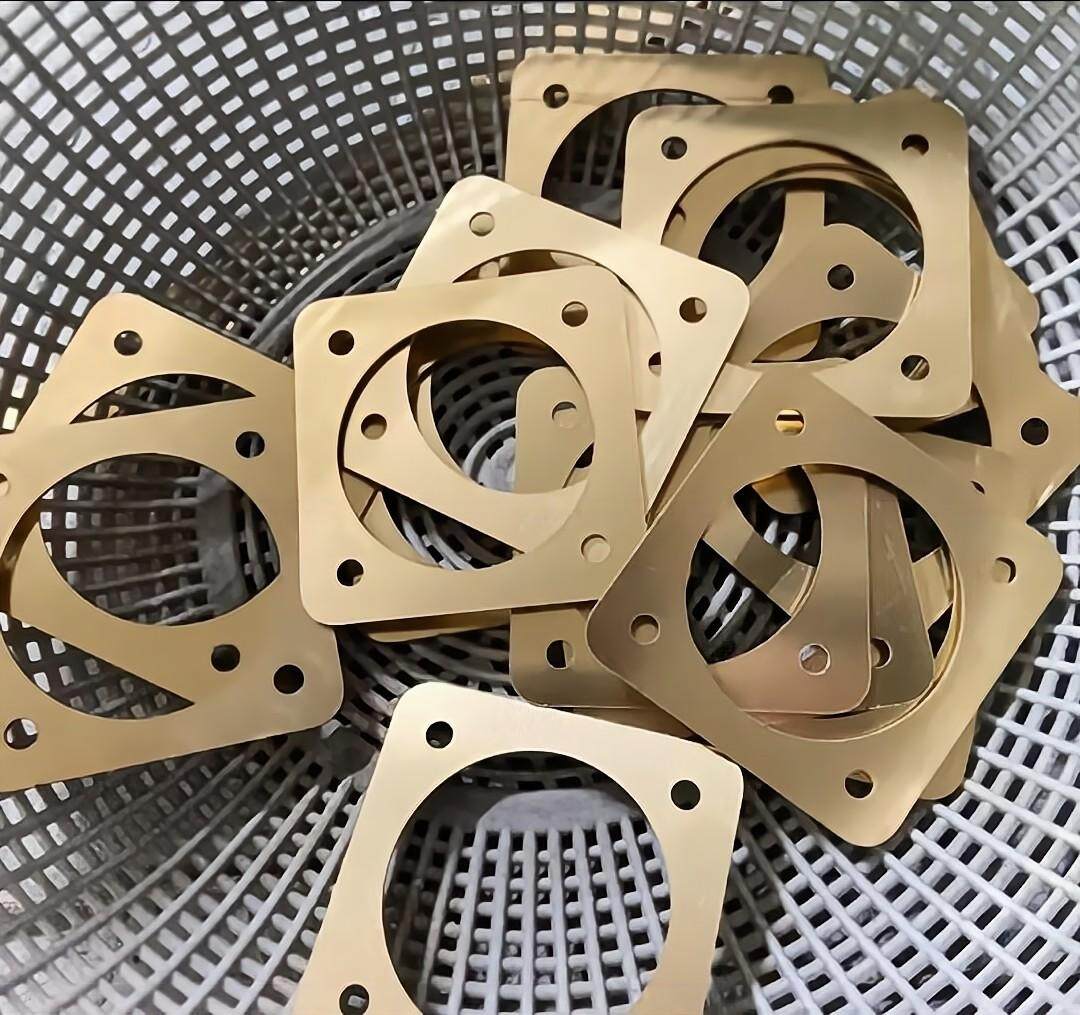

Copper Cutting Parts Feature - Custom Cnc Metal Cutting Service Suppliers

Excellent Conductivity: Copper cutting parts excel in electrical conductivity, ensuring efficient and reliable electrical connections. They are perfect for applications that require superior electrical performance. Trust our copper cutting parts for your projects.

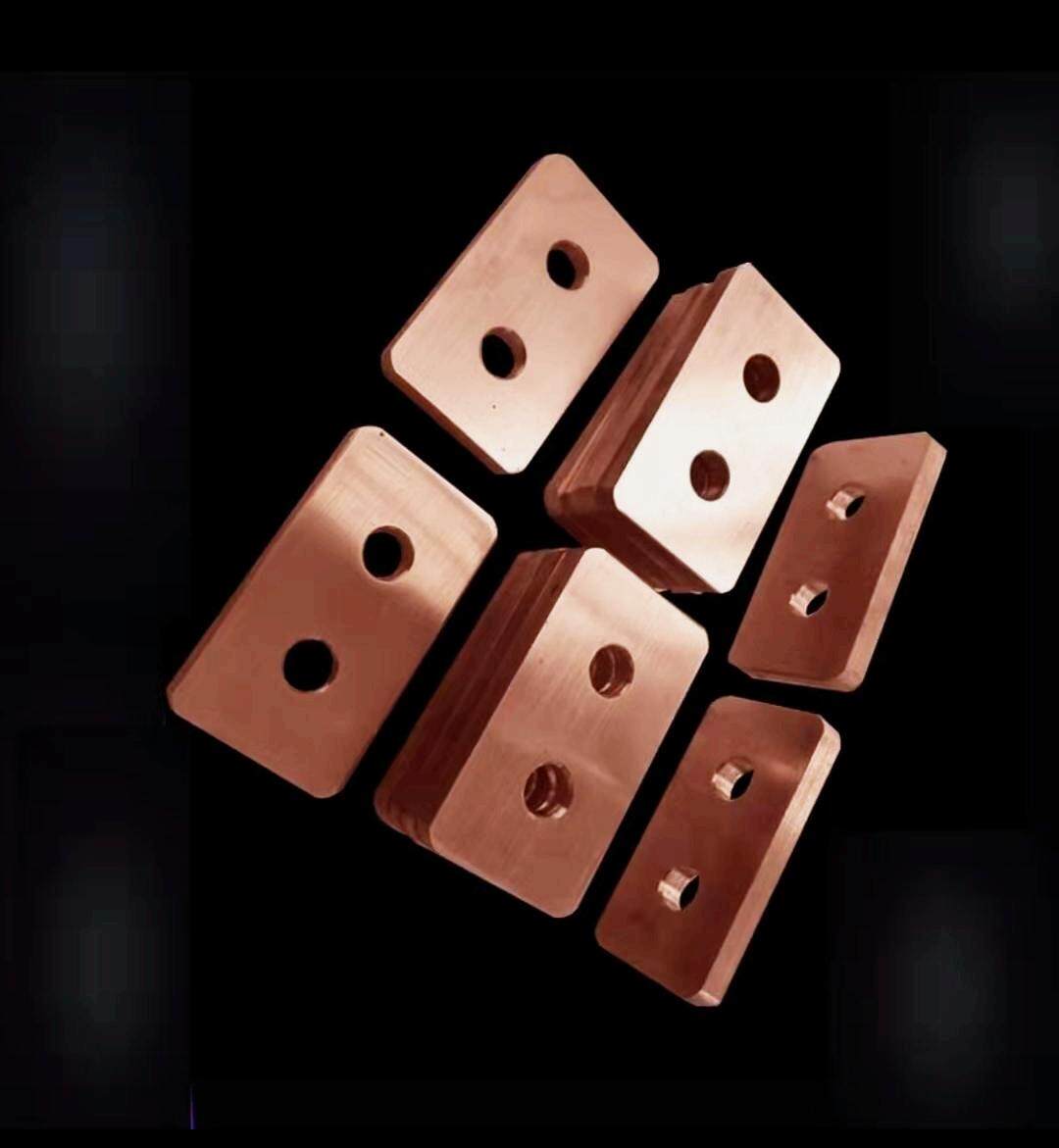

High Thermal Conductivity Promotes Heat Dissipation: Copper’s high thermal conductivity enables efficient heat dissipation, making it ideal for applications that require effective heat management. This feature is particularly crucial in electronic devices, power distribution systems, and heat exchangers.

Superior Machinability is Easy to Custom Parts: Copper’s malleability makes it highly machinable and easily shaped into custom parts. This characteristic allows for the production of precise and intricate copper cutting parts that can be tailored to meet specific project requirements.

Resistance to Corrosion for Long-term Usage: The natural resistance to corrosion ensures exceptional durability, making it an excellent choice for long-term use. Our copper cutting parts can withstand harsh environmental conditions and maintain their performance over time.

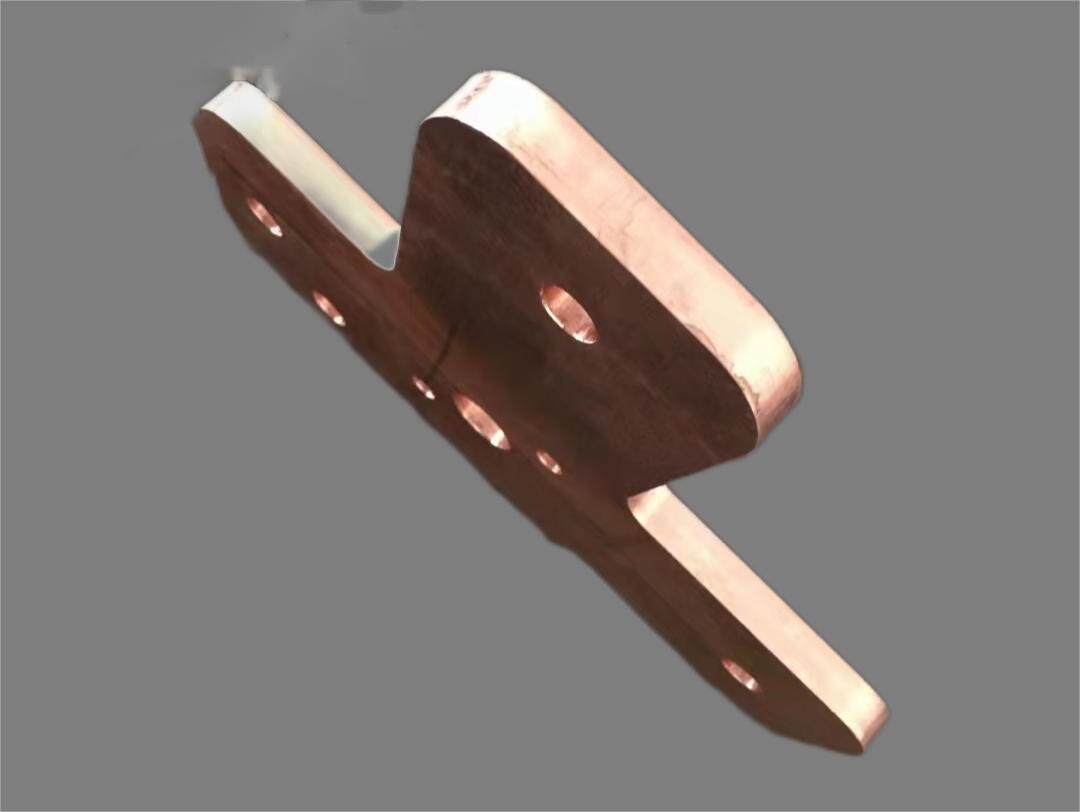

Copper Cutting Parts Advantages - Custom Cnc Metal Cutting Service Suppliers

Good Ductility to Form Complex Shapes: Copper’s high ductility enables effortless shaping and forming into complex designs or intricate parts. This flexibility allows for the production of customized copper cutting parts that precisely meet specific dimensional requirements.

Durable Material Makes It Keep Well in Extreme Environment: Copper is an exceptionally durable material known for its ability to withstand harsh conditions and frequent use. When it comes to cutting parts, copper offers unparalleled longevity and performance, making it a reliable choice for equipment in various industries.

Environmental Friendly Due to the Reused Performance: Copper is an incredibly recyclable material that can be reused without any loss in its inherent properties. The recycling process of copper not only helps in conserving precious natural resources but also plays a vital role in waste reduction. This makes copper an environmentally friendly choice for manufacturing cutting parts, as it promotes sustainability and minimizes the impact on the environment.