Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

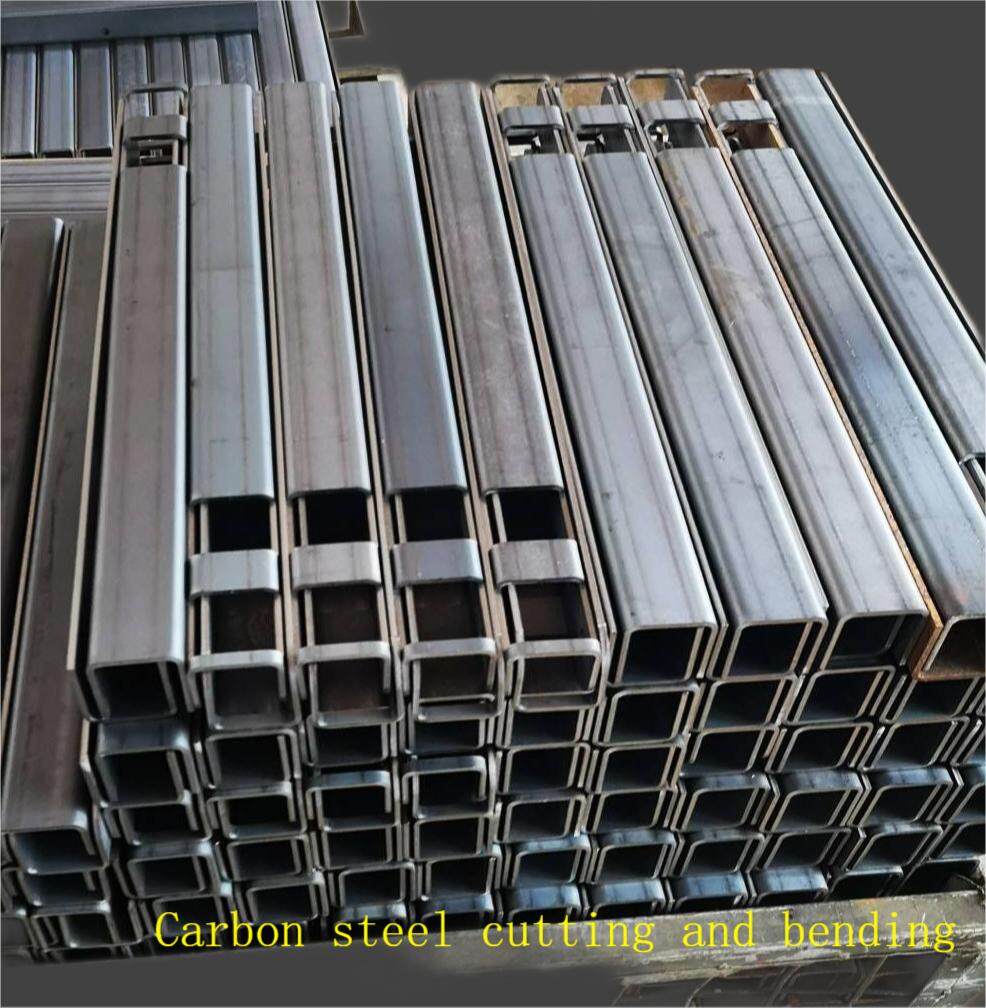

Sheet Metal Cnc Laser Cut Exporter Factory

What Are the Advantages of Using Galvanized Cable Tray

wholesale cable tray price manufacturers

Hot-dip galvanized cable tray has very good performance characteristics, which can be anti-corrosion, long life, moisture-proof, and other excellent characteristics, so what are the effects of using hot-dip galvanized cable tray, I will introduce to you below.

What are the advantages of using galvanized cable tray?

- When we are using the hot-dip galvanized cable tray, a small part of the galvanized layer on the surface has fallen off in a small place, so that the inner steel is exposed, so the other galvanized layers around will sacrifice the anode, or It can well protect the internal steel from corrosion. Unlike other material coatings, it can rust the steel and cause the entire coating to slowly peel off.

- The consumption of galvanized layer is very slow in an ordinary atmospheric environment, about 8 to 10 times the corrosion rate of steel, so it can be seen that it is much longer than the coating of any other material.

- Under some special environmental requirements, the thickness of the galvanized layer directly determines the service life of the coating. The thickness of the steel also directly determines the thickness of the coating, that is to say, the thicker the steel, the easier it is to coat with a thicker coating, so the steel of the same structure must be plated with thicker steel on thicker steel. The coating is required to ensure that the back of the use is longer.

- Hot-dip galvanized coating is the most widely used surface treatment for protecting steel, the best anti-corrosion effect, the best economic benefit, and the longest service life.

The difference between galvanized cable tray and metal cable tray

Galvanized cable tray

The supporting connecting bolts of the galvanized cable tray bracket should be ordered according to the specific requirements and models. The surface treatment of the galvanized cable tray bracket mainly includes two processes: painting and galvanizing. In a heavily corrosive environment, the galvanizing process can be used. Common thicknesses of galvanized cable trays are 1.0mm, 1.2mm, 1.5mm, 2.0mm, 2.2mm, 2.5mm, etc. 1.0mm thickness is generally suitable for galvanized cable trays with width <=100mm.

Metal cable tray

When the metal cable tray is laid in the suspended ceiling, if the suspended ceiling cannot be accessed by people, an inspection hole should be left to facilitate the subsequent maintenance of the tray. When laying the metal cable tray, the pallet ladder should be firm and reliable, and it should be flat in both horizontal and vertical directions.

The technology of galvanized cable tray

The galvanizing process is divided into electro-galvanizing and hot-dip galvanizing. The purpose of electrogalvanizing is to prevent the corrosion of steel parts, improve the corrosion resistance and service life of the steel substrate, and also increase the aesthetics of the product. In order to prolong the service life of steel, electrogalvanizing is generally used for treatment. Hot-dip galvanizing is the use of metal dissolution technology to make liquefied zinc react with the surface of the iron base of the cable tray to form a zinc-iron alloy film first, with a zinc layer in the middle, and a carbon oxide film formed by zinc and oxygen on the outermost surface. Hot-dip galvanizing is referred to as hot-dip galvanizing.

Conclusion

For more information about galvanised cable tray,cable tray price,heavy duty cable tray, we are glad to answer for you.